The world’s largest cargo aircraft | The Antonov AN-225 Mriya available for charter

Shipping PPE from China, Malaysia, India and Vietnam to the US and South America at the best prices.

AirCharter offers Antonov AN-225 Mriya – the world’s heaviest aircraft at competitive prices.

The Antonov AN-225 is the largest aircraft in the world and is the only aircraft that features six turbofan engines. It has the capability to transport up to 250 tonnes of cargo, including single pieces weighing up to 200 tonnes over short and medium haul routes. ‘Mriya’ – meaning ‘Dream’ in Ukrainian – entered commercial service in 2001. Originally developed to transport the Energiya carrier-rocket and Buran space shuttle, it has since garnered 242 world records across a 30-year period.

Based on the AN-124 design, the Antonov AN-225 has similar loading capabilities as its forerunner (cranes, winches), but boasts a longer internal cabin (43.3 m versus 36.5 m) and higher payload (250,000 kg versus 150,000 kg).

Since its maiden flight on December 21, 1988, the Antonov AN-225 has delivered heavy and outsize shipments across the globe. It is scheduled to remain in service until at least 2033.

| Antonov | AN-225 Mriya |

| Maximum Payload | 250,000 kg (551155 lbs) |

| Maximum Volume | 1,200 CBM |

| Cargo Cabin LWH | 43.3 x 6.4 x 4.4 m (1704.7 x 251.9 x 173.2 in) |

| including Ramp | 45.4 x 6.4 x 4.4 m (1787.4 x 251.9 x 173.2 in) |

| Cargo Door WH | 6.4 x 4.4 m (251.9 x 173.2 in) |

| On-Board Crane | 30,000 kg (66 138.67 lb) lift |

The Antonov AN-225 as satellite launcher

The largest cargo plane in the world is now back in the space game – helping China to launch its satellites. The Aerospace Industry Corporation of China (AICC) has just inked a deal with Antonov that will see the design and development of a new type of AN-225 that will have heavier lifting capabilities. The Chinese plan to use the Antonov AN-225 to carry satellites (on its back) and launch from seven miles (12,000m) into space. The satellite launch industry is worth more than $200 billion, a space race the Chinese are keen to profit from.

The Antonov An-225 Mriya (Ukrainian: Антонов Ан-225 Мрія, lit. ‘dream’ or ‘inspiration’; NATO reporting name: Cossack) is a strategic airlift cargo aircraft that was designed by the Antonov Design Bureau in the Ukrainian SSR within the Soviet Union during the 1980s. It is powered by six turbofan engines and is the heaviest aircraft ever built, with a maximum takeoff weight of 640 tonnes (710 short tons; 630 long tons). It also has the largest wingspan of any aircraft in operational service. The single example built has the Ukrainian civil registration UR-82060. A second airframe with a slightly different configuration was partially built. Its construction was halted in 1994 because of lack of funding and interest, but revived briefly in 2009, bringing it to 60–70% completion. On 30 August 2016, Antonov agreed to complete the second airframe for Airspace Industry Corporation of China (not to be confused with the Aviation Industry Corporation of China) as a prelude to commencing series production.

The Antonov An-225 was an enlargement of the successful Antonov An-124 that was initially developed for transporting the Buran spaceplane. The only Antonov AN-225 airplane was completed in 1988. After successfully fulfilling its Soviet military missions, it was mothballed for eight years. It was then refurbished and re-introduced, and is in commercial operation with Antonov Airlines carrying oversized payloads.The airlifter holds the absolute world records for an airlifted single-item payload of 189,980 kilograms (418,830 pounds), and an airlifted total payload of 253,820 kg (559,580 lb).It has also transported a payload of 247,000 kg (545,000 lb) on a commercial flight.

Development of the Antonov AN-225

An-225 carrying Buran in 1989

The lead designer of the Antonov AN-225 (and the An-124) was Viktor Tolmachev.

The Antonov An-225 was designed to airlift the Energia rocket’s boosters and the Buran orbiter for the Soviet space program. It was developed as a replacement for the Myasishchev VM-T. The Antonov AN-225 ‘s original mission and objectives are almost identical to that of the United States’ Shuttle Carrier Aircraft.

The Antonov AN-225 first flew on 21 December 1988 with a 74-minute flight from Kiev. The aircraft was on static display at the Paris Air Show in 1989 and it flew during the public days at the Farnborough air show in 1990. Two aircraft were ordered, but only one Antonov AN-225 (registration CCCP-82060 later UR-82060) was finished. It can carry ultra-heavy and oversize freight, up to 250,000 kg (550,000 lb) internally, or 200,000 kg (440,000 lb) on the upper fuselage. Cargo on the upper fuselage can be 70 m (230 ft) long.

The second Antonov AN-225 was partially built during the late 1980s for the Soviet space program. Following the collapse of the Soviet Union in 1991 and the cancellation of the Buran space program, the lone operational An-225 was placed in storage in 1994. The six Ivchenko-Progress engines were removed for use on An-124s, and the second uncompleted the Antonov AN-225 airframe was also stored. When it became clear that a cargoliner bigger than the An-124 was needed, the first An-225 was re-engined and put back into service.

An-225 at Farnborough in 1990

By 2000, the need for additional the Antonov AN-225 capacity had become apparent, so the decision was made in September 2006 to complete the second An-225. The second airframe was scheduled for completion around 2008, then delayed. By August 2009, the aircraft had not been completed and work had been abandoned. In May 2011, the Antonov CEO is reported to have said that the completion of a second An-225 Mriya transport aircraft with a carrying capacity of 250 tons requires at least $300 million, but if the financing is provided, its completion could be achieved in three years. According to different sources, the second aircraft is 60–70% complete.

Airspace Industry Corporation of China (AICC)’s president, Zhang You-Sheng, told a BBC reporter that AICC first contemplated cooperation with Antonov in 2009 and contacted them in 2011. AICC intends to modernize the second unfinished Antonov AN-225 and develop it into an air launch to orbit platform for commercial satellites at altitudes up to 12,000 m (39,000 ft).

In April 2013, the Russian government announced plans to revive Soviet-era air launch projects that would use a purpose-built modification to the Antonov AN-225 as a midair launchpad.

In August 2016, representatives from Ukraine’s Antonov and AICC, an import-export company operating out of Hong Kong, signed an agreement to recommence production of the Antonov AN-225 , with China now planning to procure and fly the first model by 2019. The aviation media cast doubt on the production restart, indicating that due to the ongoing Russia–Ukraine conflict needed parts from Russia are unavailable, although they may be made in China instead.

On 25 March 2020, the freighter commenced a series of test flights from Hostomel Airport near Kiev, after more than a year out of service for the installation of a domestically-designed power management and control system.

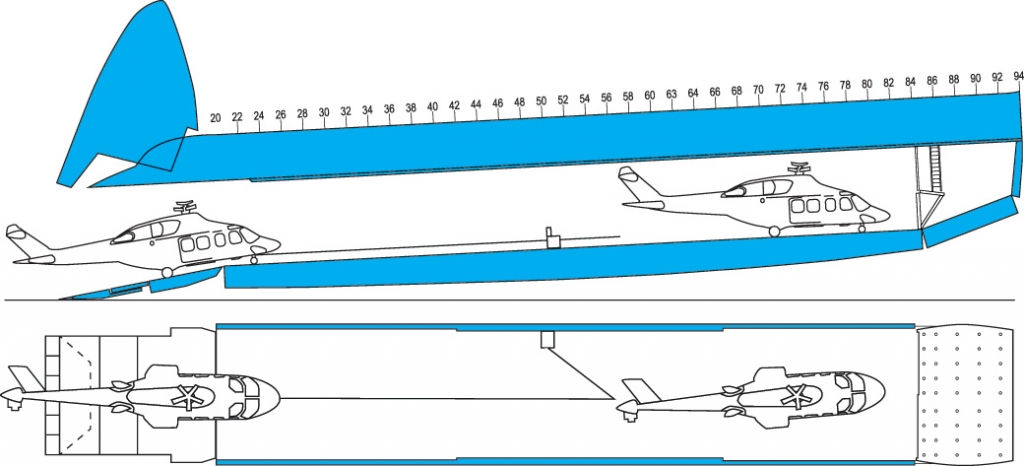

Loading Equipment on the Antonov AN-225 Mriya

|

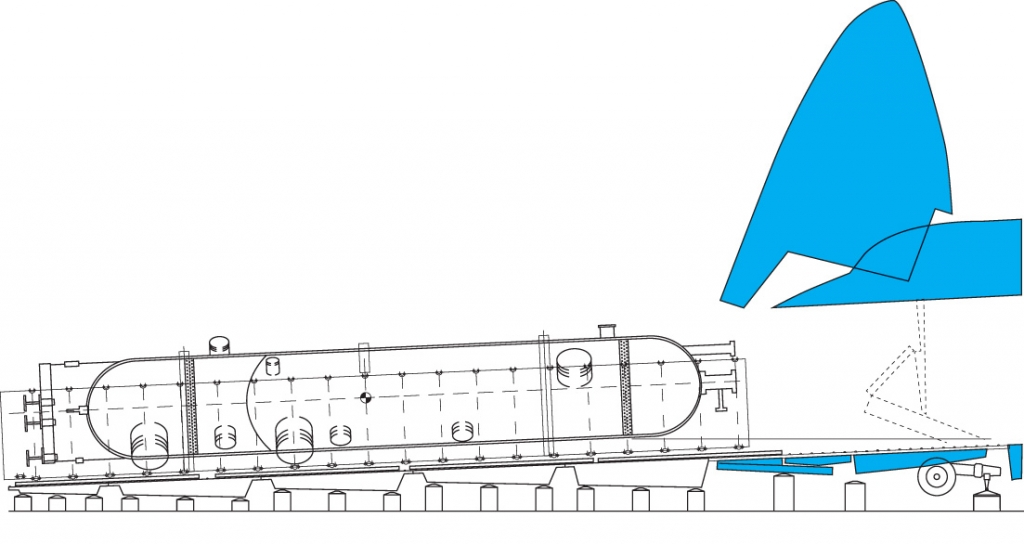

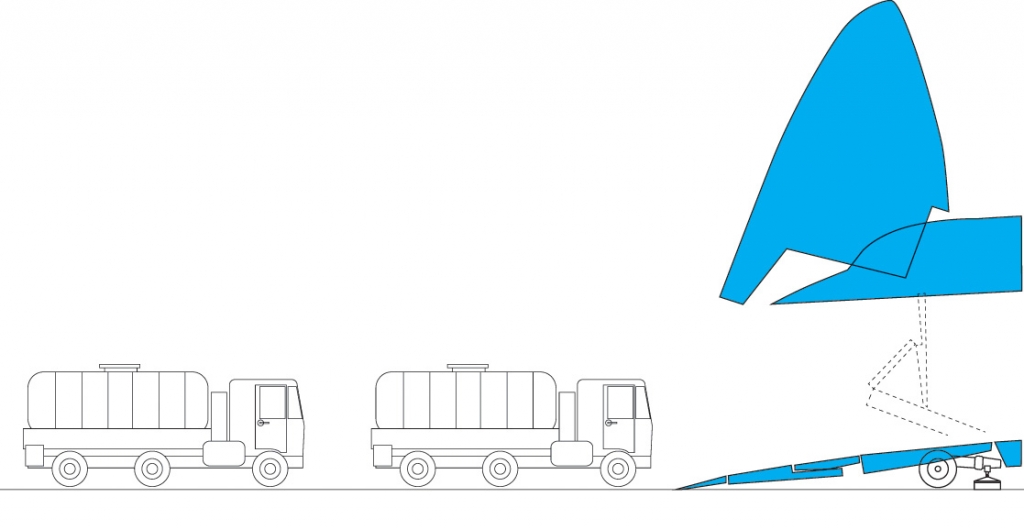

Loading of oversized and super heavy cargoes with weight up to 200,000kg (440,000lbs) – using OPTG-120M loading equipment and external cranesThe OPTG-120M ramp system is the strongest and most rigid ramp system on the market. It has been designed and manufactured by Antonov Airlines to load heavy and oversized pieces. Advantages of the OPTG-120M ramp system:

The OPTG-120M ramp system is used in the transportation of heavy pieces on the AN-124-100/150M and the Antonov AN-225 aircraft. It allows the loading and unloading of cargo with a maximum weight of 200,000 kg (440,000 lbs) (for the Antonov AN-225 ) and height of 4.1 m (13 ft 5 in) (both the Antonov AN-225 and AN-124). |

|

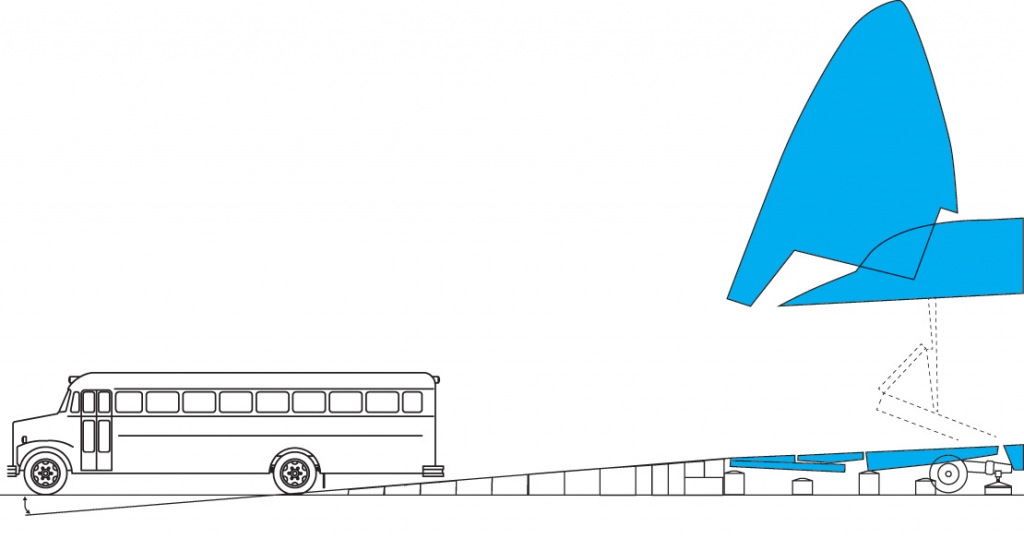

Loading of vehicles with low ground clearance – using OZDKG loading equipmentThe OZDKG ramp is a special piece of external equipment intended for loading and offloading long and heavy-wheeled vehicles into the AN-124-100/150M and the Antonov AN-225 aircraft. Generally used when parameters like length, road clearance and the weight of vehicle will not allow loading via the aircraft’s own integral ramp. Basic parameters:

|

|

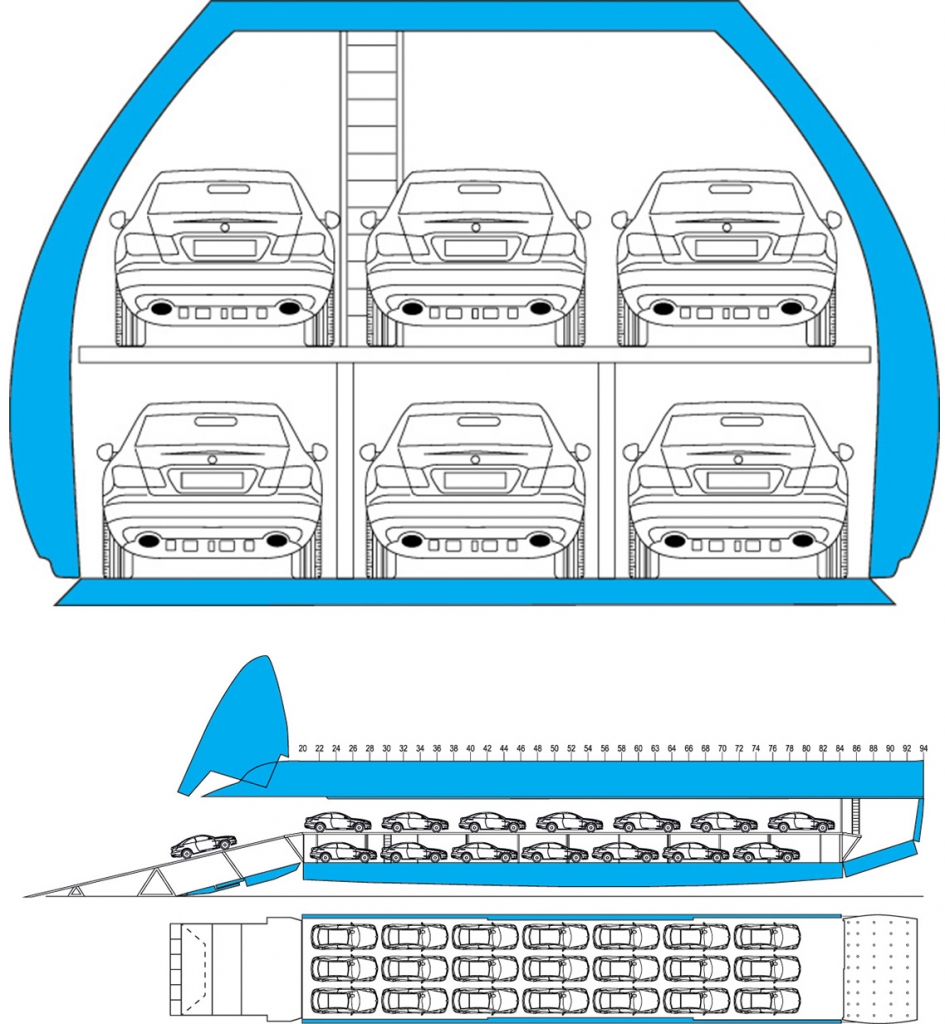

Loading of cars – using car rack system in the Antonov AN-225The Antonov AN-225 ’ Car Rack System is a special double-deck loading system allowing up to 50 cars to be loaded on two levels. Subject to vehicle dimensions and weight, cars can simply be driven onboard. The the Antonov AN-124-100/150M has the unique ability to adapt its floor loading capacity for the transport of multiple vehicles. The use of the double-deck loading system means that twice the floor area can be used for the accommodation of vehicles such as saloons, rally cars and certain types of 4 x 4s. |

|

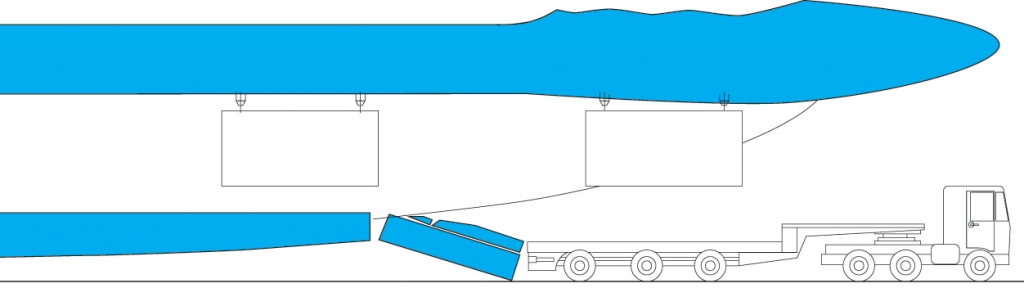

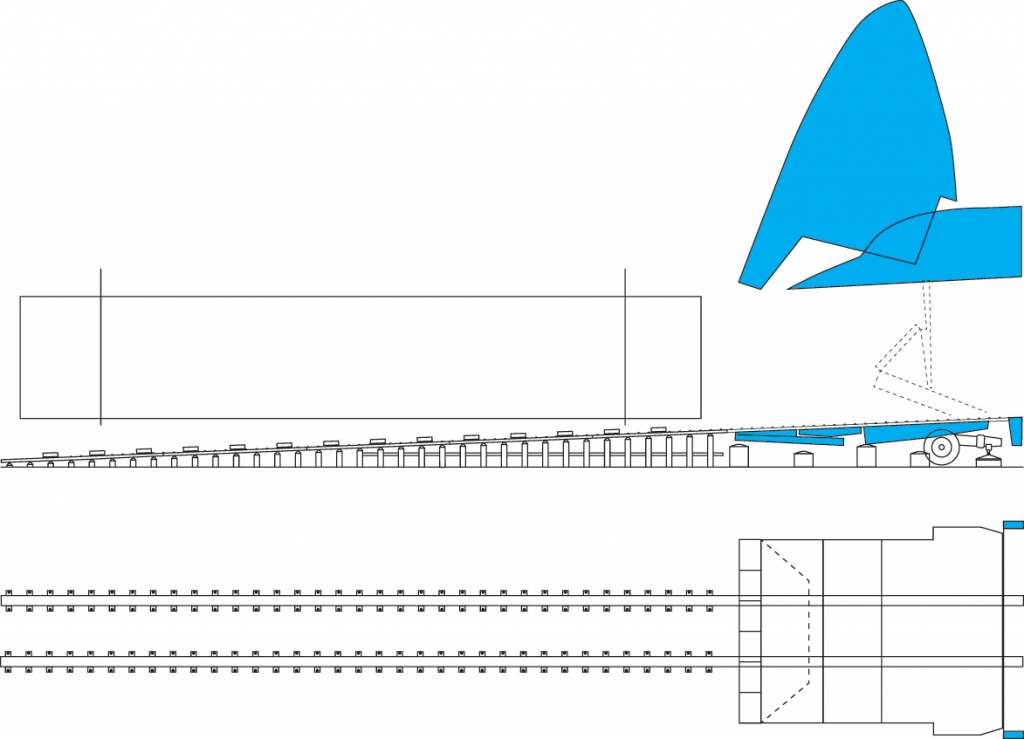

Loading of cargoes with weight up to 30,000 kg (66,139 lbs) using aircraft internal cranes via rear cargoBoth the Antonov AN-124-100/150M and the Antonov AN-225 aircraft contain an onboard crane system designed and utilized for the loading and unloading of single pieces weighing up to 30,000 kg (66,139 lb). Cargo can be delivered to the Antonov AN-225’s rear cargo door on trailers/trucks, from which it can be lifted by the aircraft’s bridge cranes using four hooking points. The AN-22A also contains an onboard crane system capable of lifting pieces weighing up to 10,000 kg (22,046 lb). Cargo loaded by this method must have suitable lifting points and a balanced CoG (Centre of Gravity) to safely load such pieces. |

|

Loading using aircraft winchesBoth the Antonov AN-124-100/150M and the Antonov AN-225 aircraft contain an onboard winch system capable of handling single pieces weighing up to 120,000 kg (264,555 lbs) (AN-124-150M) and 200,000 kg (440,000 lbs) (Antonov AN-225 ). Generally used in conjunction with a ramp system and external cranes, the Antonov AN-225 aircraft’s onboard winch system is arranged using a loading pulley block system depending on the weight of item to be loaded. |

|

Loading via nose and rear cargo rampsLoading of self-propelled vehicles via nose and rear cargo ramps of the Antonov AN-225 is the simplest method of loading the AN-124-100/150M and the Antonov AN-225 aircraft. The the Antonov AN-225 aircraft nose door is opened, the aircraft ‘kneels’, its ramp is unfolded, and vehicles are simply driven into the cargo hold. Loading can be carried out through the nose cargo door and offloading via the rear cargo door. |

|

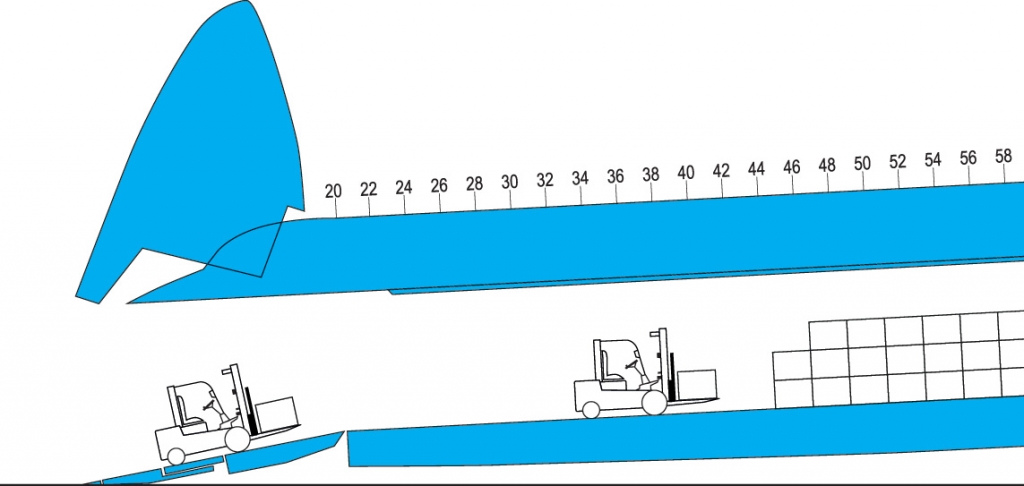

Loading of general cargo using forkliftLoading of general cargo on the Antonov AN-225 using forklift – another simple method of loading. Forklifts can be used for loading and offloading of wooden pallets, small crates and similar items through the nose cargo door. Forklifts are not the property of airline and are not carried on the aircraft, but they can provided locally with prior notice. |

|

Loading of tall pieces with height up to 4.27 m (168 in) – using OPKG-50 loading equipment and external cranesThe OPKG-50 ramp system is a unique, low profile skate-type loading equipment intended for loading and offloading oversized cargo weighed up to 50,000 kg (110,231 lbs) into the AN-124-100/150M and the Antonov AN-225 aircraft. Although the system is similar to the OPTG-120M ramp system, it allows the loading of higher, but lighter pieces. However, the loading concept is the same as the OPTG-120M ramp system. OPKG -50 ‘Next Generation’ Ramp System:

|

Call our cargo specialist at 1 (415) 464-0400

Hawker-Beechcraft Hawker 400XP

Hawker-Beechcraft Hawker 400XP Cessna Citation V

Cessna Citation V Beechcraft Premier IA

Beechcraft Premier IA Beechcraft King Air 350

Beechcraft King Air 350